T: +86-15888736999

No.67, Wutong Rd, Three-Two Rd Binhai Industrial Park, Economic & Technoloical Development Zone, Wenzhou, Zhejiang, China

Views: 0 Author: Site Editor Publish Time: 2025-07-09 Origin: Site

You will find the best valve choice depends on your specific application. Diaphragm valves work well when you need precise control, cleanliness, or resistance to corrosive media. Ball valves handle high-flow and high-pressure tasks, offering quick shutoff and durability. Engineers often focus on valve size, pressure rating, and flow coefficient (Cv) to match performance needs. Correct sizing prevents issues like poor control and instability, making it important to select diaphragm valves or ball valves based on your process demands.

Diaphragm valves offer precise flow control and prevent contamination, making them ideal for clean and sensitive processes.

Ball valves provide fast shutoff and handle high pressure and flow, perfect for tough industrial and high-demand applications.

Maintenance is easier and less frequent with ball valves, while diaphragm valves need regular diaphragm replacement to avoid leaks.

Choose diaphragm valves for sterile, chemical-resistant, and low-contamination environments like pharmaceuticals and food processing.

Select ball valves for high-pressure, high-temperature, and quick-operation needs in industries like oil, gas, and water treatment.

Consider fluid type, pressure, temperature, and hygiene needs carefully to match the valve to your system's requirements.

Proper valve sizing and maintenance planning reduce downtime and improve system reliability for both valve types.

Automation is possible for both valves, enhancing control and efficiency in modern industrial processes.

When you compare diaphragm valves and ball valves, you notice several key differences that affect how you use them in your system. You want to choose the right valve for your needs, so understanding these key differences helps you make a smart decision.

Here is a table that highlights the key differences between these two valve types:

Aspect | Diaphragm Valve | Ball Valve |

|---|---|---|

Flow Control | Precise, accurate flow regulation; best for sensitive processes needing fine adjustments | High flow capacity; quick on/off control; not good for fine regulation |

Pressure | Handles moderate pressures (up to ~300 psi) and temperatures (up to ~450°F) | Handles high pressures and temperatures; robust for tough industrial environments |

Maintenance | Needs more frequent maintenance due to diaphragm wear; servicing can be complex and costly | Low maintenance; durable; less frequent servicing; simple operation reduces leak risk |

Applications | Best for contamination prevention and chemical resistance (pharmaceuticals, food processing) | Common in high-pressure, high-temperature systems (oil, gas, water treatment) |

Tip: You can quickly spot the key differences by looking at flow control, pressure limits, and maintenance needs.

To help you scan the key differences even faster, here are the main points:

Diaphragm valves give you precise control. You use them when you need to avoid contamination or handle corrosive fluids.

Ball valves let you move large amounts of fluid quickly. You pick them for high-pressure or high-temperature jobs.

Maintenance is easier with ball valves. Diaphragm valves need more attention because the diaphragm wears out.

You find diaphragm valves in clean or sterile environments. Ball valves work best in tough, industrial settings.

You see these key differences in action when you select a valve for your project. If you need fine adjustments and a clean process, you go with a diaphragm valve. If you want fast shutoff and durability, you choose a ball valve. Knowing these key differences saves you time and money, and it helps your system run smoothly.

You use diaphragm valves when you need reliable flow control and high precision. These valves use a flexible diaphragm that moves up or down to open or close the flow path. You can operate them manually or automatically. When you press the diaphragm against the valve seat, you stop the flow. When you lift it, you allow fluid to pass. This design keeps the fluid away from moving parts, which helps you prevent contamination and maintain purity.

You often see sanitary diaphragm valves made from materials like EPDM, PTFE, or TFM for the diaphragm and stainless steel for the body. These materials give you strong chemical resistance and durability. Technical datasheets show that you can choose from different body types, such as forged or cast, and select bonnet assemblies for manual or sealed operation. You also find flow coefficients (Cv) listed, which help you size the valve for your system. Manuals and datasheets provide you with details on operation, maintenance, and compliance with standards like ASME BPE.

Note: The simple mechanism of diaphragm valves gives you excellent shut-off, minimal pressure drop, and precise throttling control. You can use them in fully open, throttling, or fully closed positions, which makes them versatile for many engineering needs.

You get several strengths when you choose sanitary diaphragm valves:

Precision: You achieve fine flow control and accurate adjustments, which is important for sensitive processes.

Hygiene: You keep fluids isolated from moving parts, which supports zero tolerance for contamination.

Chemical resistance: You handle aggressive chemicals without damaging the valve.

Precision control: You can throttle flow with high accuracy, which is essential for dosing or mixing.

Low-flow suitability: You maintain control even at low flow rates, which is hard for other valves.

Leak-proof sealing: You reduce the risk of leaks, which protects your process and equipment.

Sanitary diaphragm valves excel in environments where you need precision, hygiene, and reliability. You often see them in pharmaceutical, food, and biotech industries, where cleanliness and control matter most.

Tip: You should avoid using diaphragm valves for high-pressure or high-temperature applications. They do not perform well in extreme cold or heat, and the diaphragm can wear out faster under severe conditions.

You find sanitary diaphragm valves in many industries that demand strict hygiene and precision. Common applications include:

Pharmaceutical manufacturing, where you need sterile flow control.

Food and beverage processing, where you require zero tolerance for contamination.

Water treatment plants, where you need reliable chemical dosing and isolation.

Chemical processing, where you benefit from strong chemical resistance and precise control.

When you size a diaphragm valve, you look at flow rates, pipe size, and pressure differential. For example, if you need a maximum flow of 3,500 gpm and a pressure differential of 30 psi, you calculate the Cv to select the right valve size. You also decide if the valve will run continuously or only sometimes. This helps you match the valve to your process needs.

You choose sanitary diaphragm valves when you want precision, hygiene, and safe flow control. They give you the confidence to run sensitive processes without risking contamination or leaks.

You use ball valves when you need fast and reliable flow control. These valves have a simple design. Inside the valve body, a spherical ball sits with a hole through its center. When you turn the handle 90 degrees, the ball rotates. If the hole lines up with the pipe, fluid flows freely. If you turn the ball, the solid side blocks the flow. This quarter-turn action gives you quick shutoff and easy operation.

Ball valves come in different body styles, such as two-piece, three-piece, and forged designs. You often see stainless steel, carbon steel, brass, or bronze used for the body. The choice of material affects how well the valve resists corrosion and handles tough environments. Seats made from PTFE or reinforced composites help the valve seal tightly and last longer, even in high-pressure or high-cycle situations. You can operate these valves manually or use electric, pneumatic, or hydraulic actuators for automated control.

Note: Ball valves offer full bore flow, which means the opening matches the pipe diameter. This design reduces pressure drop and keeps flow efficient.

Ball valves give you several important advantages:

Rapid shutoff: You can stop flow instantly with a simple quarter-turn.

High flow capacity: The full bore design allows large volumes of fluid to move with minimal resistance.

Pressure and temperature tolerance: Many ball valves handle pressures up to 10,000 psi and temperatures up to 450°F, depending on the material.

Durability: The robust construction and quality seat materials help the valve last through thousands of cycles.

Low maintenance: You spend less time and money on upkeep because the design resists wear and leakage.

Versatility: You can use ball valves for on/off service or basic flow control in many systems.

Studies show ball valves outperform other types in high-flow and high-pressure applications. They also provide excellent sealing, with leakage rates as low as 0.0001% of rated flow. Automated ball valves offer precise control, fast response, and long service life. You find that proper sizing and installation further improve performance and reliability.

Strength | Description |

|---|---|

Quick shutoff | Quarter-turn operation for immediate isolation |

High flow coefficient | Efficient flow control with low pressure loss |

Robust sealing | PTFE or composite seats ensure minimal leakage |

Long cycle life | Over 25,000 cycles in industrial use |

Cost-effective | Lower maintenance and lifecycle costs compared to other valve types |

Tip: Ball valves work best when you need fast, reliable isolation and high flow rates. They do not provide fine flow control or precise throttling.

You see ball valves in many industries because they handle tough jobs and require little maintenance. Common uses include:

Oil and gas production, where you need quick shutoff and high-pressure resistance.

Chemical processing, where corrosion resistance and leak prevention matter.

Water treatment plants, where reliable flow control and durability are essential.

Power generation, where you need valves that withstand high temperatures and frequent cycling.

Ball valves also fit well in systems with automated control. Electric or pneumatic actuators let you operate the valve remotely and respond quickly to process changes. You can use ball valves for viscous fluids, slurries, and even cryogenic applications with the right materials.

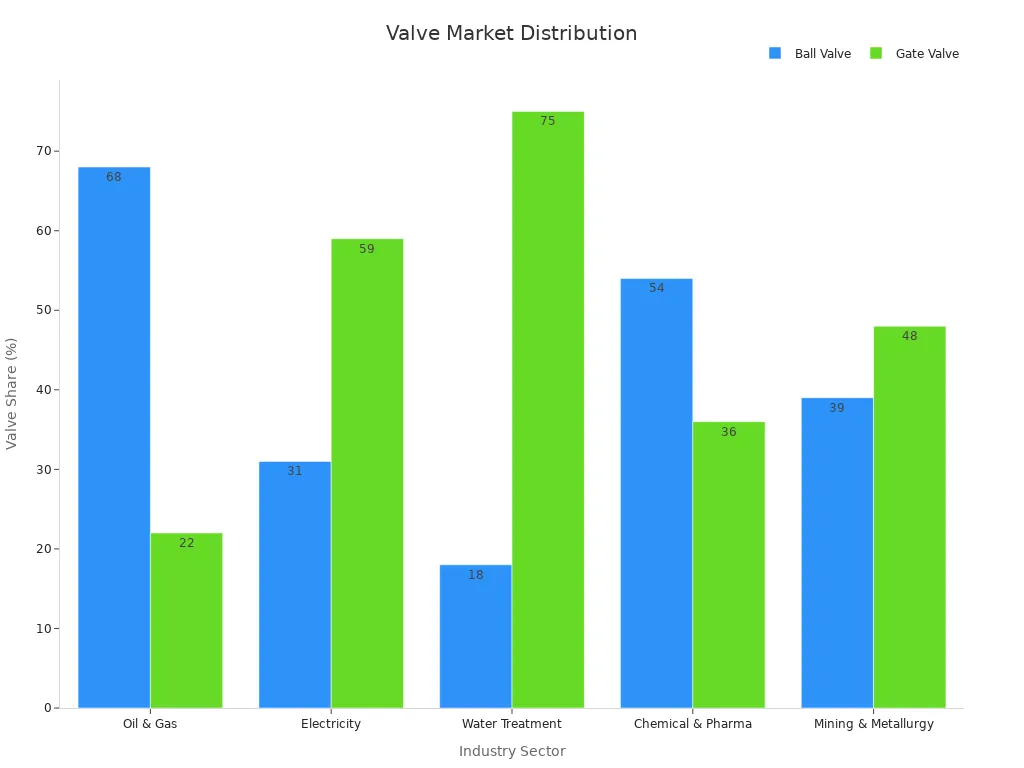

The chart above shows how ball valves dominate the oil and gas sector due to their high frequency and zero leakage performance. They also have a strong presence in chemical, mining, and power industries. You should avoid using ball valves in systems that need precise flow control or sterile conditions, such as pharmaceutical dosing or ultra-clean water systems. In those cases, diaphragm valves or other specialized valves work better.

Remember: Ball valves give you speed, strength, and simplicity. You get the most value when you match them to the right application and operating limits.

You want a valve that matches your system's needs. Ball valves give you fast, reliable shutoff. You turn the handle a quarter turn, and the flow stops or starts right away. This makes ball valves perfect for emergency situations or when you need to move large amounts of fluid quickly. They handle high pressure and temperature, so you see them in tough industrial jobs.

Diaphragm valves work best when you need precision and careful flow control. You get gradual, smooth adjustments, which helps in dosing or mixing. The flexible diaphragm inside these valves adapts to pressure changes and keeps the flow steady. You also get excellent leak resistance, which protects your process from contamination.

Performance Metric | Ball Valves | Diaphragm Valves |

|---|---|---|

Flow Control | Quick shutoff, high flow, poor throttling | Fine control, gradual response, good for dosing |

Pressure Handling | High pressure, robust sealing | Moderate pressure, flexible diaphragm |

Seal & Leakage | Tight shutoff, seals may wear | Enhanced leak resistance, diaphragm fatigue possible |

Response Time | Fast, ideal for emergencies | Slower, better for sensitive adjustments |

Tip: Choose ball valves for speed and strength. Pick diaphragm valves for precision and contamination control.

You want a valve that keeps your system running with little downtime. Ball valves need regular cleaning and inspection, usually once a year. In dirty environments, you may need to check them more often. You lubricate moving parts and look for leaks or corrosion. Ball valves are easy to repair, and you can replace worn parts during scheduled shutdowns.

Diaphragm valves need a different approach. The diaphragm inside wears out over time, especially if you use it with harsh chemicals or change temperatures often. Some plants replace diaphragms every six months, even if they look fine. This can raise costs, but it prevents leaks and failures. Newer diaphragm valves make replacement faster and easier, so you spend less time on maintenance.

Ball valves: predictable maintenance, easy repairs, low cost.

Diaphragm valves: scheduled diaphragm replacement, careful handling, improved service intervals.

Note: Preventative maintenance programs help you avoid unexpected downtime and keep both valve types working longer.

You want to balance your budget with performance. Ball valves usually cost less to buy. They offer a simple design and low maintenance, which saves you money at first. If you need advanced features or sanitary ball valves, the price goes up.

Diaphragm valves cost more upfront, especially if you choose premium materials or automation. However, you get a longer lifespan and less downtime from contamination or cleaning. Over time, diaphragm valves can save you money because they reduce maintenance and keep your process cleaner.

Cost Factor | Ball Valves | Diaphragm Valves |

|---|---|---|

Initial Purchase | Lower | Higher (premium materials, automation) |

Lifespan | Standard | Up to 40% longer |

Maintenance Downtime | Higher | Reduced by up to 30% |

Contamination-related Downtime | Higher risk | Reduced by up to 25% |

Total Cost of Ownership | Potentially higher | Lower over time |

Remember: Diaphragm valves may cost more at first, but they often pay off with lower total costs and better process protection.

When you select a valve for your system, you want to know which type fits your application best. Diaphragm valves and ball valves each have strengths that make them ideal for certain industries and processes. You need to look at the type of fluid, the need for cleanliness, and how much control you want over flow.

Diaphragm valves give you precise flow control and excellent resistance to corrosion. You often see them in industries where hygiene and contamination control matter most. For example, in pharmaceutical and biotech plants, you use diaphragm valves to keep processes sterile. These valves prevent contamination because the fluid never touches moving parts. You also find diaphragm valves in the oil and gas industry. They handle abrasive and corrosive fluids well, which helps protect your equipment and reduce downtime. Their bi-directional sealing and ability to meter flow make them a top choice for critical regulation tasks.

Ball valves work best when you need fast shutoff and high flow rates. You use them in water treatment, marine, and food processing because they offer reliable sealing and quick operation. Ball valves handle high pressure and temperature, so they fit tough industrial jobs. In marine and shipping, you rely on ball valves for saltwater systems because they resist corrosion and provide a strong seal. In pulp, paper, and textile plants, ball valves lead in chemical and dyeing processes due to their durability and ease of use.

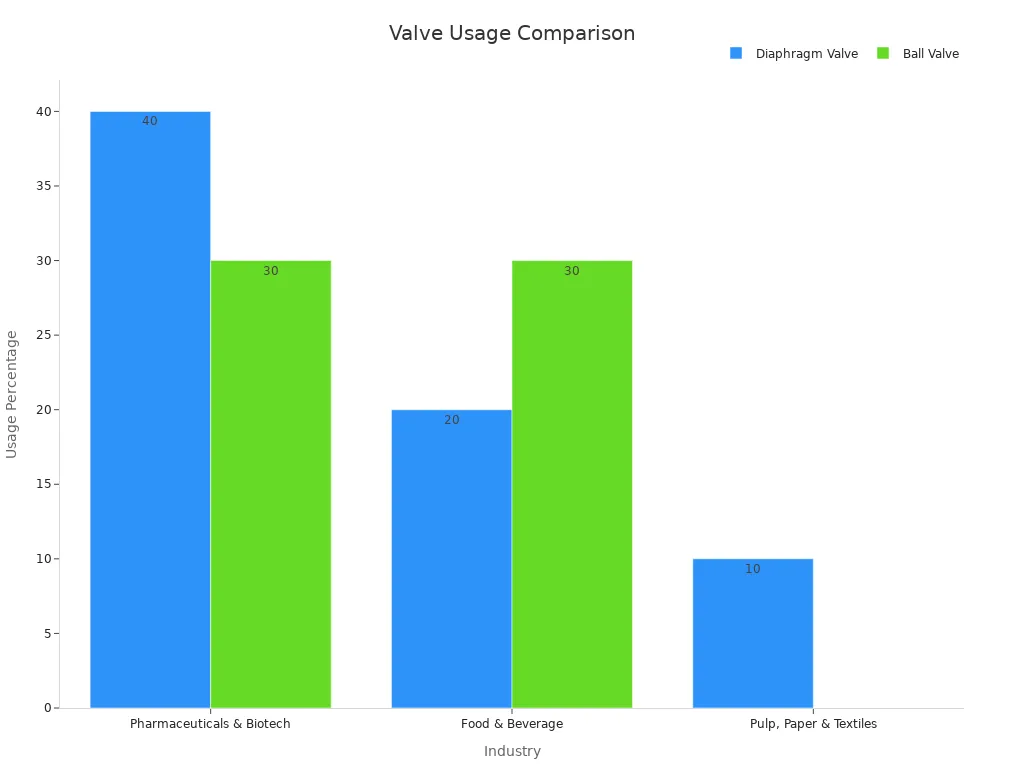

Here is a table that shows how different industries use diaphragm valves and ball valves:

Industry | Diaphragm Valves Usage | Ball Valves Usage | Key Application Highlights |

|---|---|---|---|

Pharmaceuticals & Biotech | 40% | 30% | Sterile processing, low contamination risk |

Oil & Gas | High | Moderate | Corrosion resistance, precise flow, abrasive media |

Marine & Shipping | Low | 25-30% | Saltwater systems, quick shutoff |

Food & Beverage | 20% | 30% | Cleanliness, strong seal, fast operation |

Pulp, Paper & Textiles | 10% | 30-50% | Wastewater, chemical and dyeing processes |

You can see from the table that diaphragm valves dominate in pharmaceutical and oil and gas applications. Ball valves take the lead in marine, food, and textile industries.

Tip: Choose diaphragm valves when you need precise control, hygiene, or corrosion resistance. Pick ball valves for high flow, quick shutoff, and tough environments.

You should always match the valve type to your process needs. Diaphragm valves excel in sterile, corrosive, or metering applications. Ball valves shine in high-flow, high-pressure, or rugged settings. When you understand these differences, you make better choices for your system and reduce maintenance or downtime.

You need to match the valve to the fluid in your system. Fluid properties like viscosity, density, and contamination level play a big role in your decision. Viscosity affects how easily the fluid moves through the valve and how much force you need to operate it. High-viscosity fluids require more actuation force and may need automated actuators. Density impacts the flow coefficient (Cv) and pressure drop. Compressibility matters for gases, while the Reynolds number helps you understand if the flow is laminar or turbulent.

Viscosity changes with temperature. You must check if the valve can maintain sealing and performance as viscosity shifts.

Contaminants in the fluid can clog or damage some valves. For high contamination, you may want a choke valve or a design that handles particles well.

Ball valves work well for viscous fluids. They offer excellent flow coefficients, minimal pressure drops, and good sealing.

Diaphragm valves excel with high-purity fluids. You get rapid shut-off and precise control, which is important for sensitive processes.

Tip: Always check the fluid's classification. Newtonian and non-Newtonian fluids behave differently, so you need to size and select the valve accordingly.

Here is a quick guide to help you decide:

Fluid Property | Best Valve Type | Why It Matters |

|---|---|---|

High viscosity | Ball valves | Easy flow, strong sealing, less clogging |

High purity | Diaphragm valves | No contamination, precise control |

High contamination | Choke/ball valves | Handles particles, resists clogging |

Gases (compressible) | Ball/diaphragm valves | Good sealing, control for pressure and flow |

Fluctuating viscosity | Diaphragm valves | Maintains precision and sealing across temperatures |

You should also consider piping geometry. Pipe size, layout, and fittings affect how the valve performs. The right choice keeps your system efficient and reliable.

You must consider both pressure and temperature when selecting a valve. Pressure ratings change as temperature rises. For example, a valve rated for 285 psi at 20°C may only handle 150 psi at 100°C. Material properties like tensile strength and alloy composition affect how much pressure the valve can handle as temperatures shift.

Ball valves handle high pressure and temperature well. You see them in tough industrial jobs where durability matters.

Diaphragm valves work best at moderate pressures and temperatures. Extreme heat or cold can cause the diaphragm to wear out faster.

Standards like ANSI/ASME and PN ratings help you compare pressure and temperature limits. Always check the manufacturer's pressure-temperature charts before making a choice.

Measured data such as fluid and ambient temperature, pressure, and flow rate help you monitor valve performance. Temperature changes can cause material expansion, which affects sensors and may lead to inaccurate readings. Compensation algorithms and integrated sensors help maintain accurate control.

Note: Never exceed the rated pressure or temperature for your valve. Doing so risks leaks, failures, or even safety hazards.

You need to think about hygiene if your process involves food, pharmaceuticals, or any application where contamination is a concern. Diaphragm valves stand out in these settings. Their crevice-free design and smooth surfaces prevent contamination and make cleaning easy. You get precise control and reliable sealing, which keeps your product safe.

Diaphragm valves are the top choice for sterile environments. You find them in pharmaceutical manufacturing, food processing, and clean water systems.

Ball valves are harder to clean. They have more crevices and moving parts that can trap contaminants. This makes them less suitable for hygienic applications.

Pneumatic diaphragm valves are common in automated sterile fluid control. They help you maintain strict hygiene standards with minimal manual intervention.

Hygiene tip: Always choose diaphragm valves for processes that demand sterility, easy cleaning, and contamination resistance. Ball valves work better in rugged, non-sterile environments where hygiene is not the top priority.

When you choose a valve, you want to know how much time and effort you will spend on maintenance. Maintenance affects your system's reliability and your budget. You need to look at how easy it is to service each valve, how often you need to do it, and what impact it has on your operations.

Ball valves usually give you simple maintenance. You can often service them in place. You just shut off the line, remove the handle, and replace worn parts. This design keeps downtime short and labor costs low. Ball valves have fewer moving parts, so you do not need to check them as often. You can set up a routine inspection schedule, and most issues show up during these checks.

Diaphragm valves need more attention. The diaphragm inside wears out over time, especially if you use the valve for harsh chemicals or frequent cycling. Sometimes, you must remove the valve from the line to replace the diaphragm. This process takes more time and can interrupt your workflow. You should plan for regular diaphragm replacement, even if it looks fine, to avoid leaks or failures.

Tip: Set up a routine maintenance plan for all valves. Regular checks help you spot problems early and keep your system running smoothly.

Here is a quick comparison to help you decide:

Maintenance Factor | Ball Valve | Diaphragm Valve |

|---|---|---|

Service in place | Yes, usually | Sometimes, may need removal |

Frequency | Low, annual or semi-annual checks | Higher, depends on diaphragm wear |

Labor cost | Lower, quick repairs | Higher, more complex servicing |

Downtime | Short, easy to schedule | Longer, may disrupt operations |

Spare parts | Seats, seals, handles | Diaphragms, seals, sometimes bonnet |

You should also consider the likelihood of unscheduled maintenance. Some systems see more wear due to harsh fluids or frequent use. If you expect more surprises, pick a valve that is easy to service and has available spare parts.

Ball valves: Less frequent maintenance, easy repairs, lower labor costs.

Diaphragm valves: More frequent checks, planned diaphragm replacement, possible removal for service.

By planning your maintenance, you reduce downtime and avoid costly surprises. Always keep spare parts on hand and train your team on proper servicing steps. This approach keeps your valves—and your process—working at their best.

You should choose diaphragm valves when you need clean, leak-proof service in chemical, pharmaceutical, or food applications. They isolate fluid, resist corrosion, and minimize contamination. Ball valves work best for high pressure, quick shutoff, and tough industrial jobs. They handle viscous or hazardous fluids and offer rugged durability. Use the table below to compare:

Choose When You Need... | Diaphragm Valves | Ball Valves |

|---|---|---|

Cleanability, purity, corrosion | ✔️ | |

High pressure, rapid shutoff | ✔️ | |

Precise flow control | ✔️ | |

Durability, low maintenance | ✔️ |

For complex cases, use the decision guide or consult an expert. The right choice always depends on your specific needs.

You use a diaphragm valve for precise flow control and hygiene. You pick a ball valve for quick shutoff and high flow. Diaphragm valves work best in clean or corrosive environments. Ball valves handle tough, high-pressure jobs.

You should not use a ball valve for precise throttling. It works best for on/off control. If you need fine adjustments, a diaphragm valve gives you better accuracy and control.

Diaphragm valves last longer when you handle aggressive chemicals. Their design keeps the fluid away from moving parts. You get better corrosion resistance and fewer leaks.

Yes, you can clean diaphragm valves easily. Their smooth, crevice-free design prevents contamination. You often see them in food, beverage, and pharmaceutical plants for this reason.

You spend less time maintaining ball valves. Their simple design means fewer parts wear out. You can often service them in place, which saves you time and money.

You look at your fluid type, pressure, temperature, hygiene needs, and budget. Use a table like this to help:

Need | Best Choice |

|---|---|

Precise control | Diaphragm valve |

High flow/pressure | Ball valve |

Easy cleaning | Diaphragm valve |

Low maintenance | Ball valve |

Yes, you can automate both. You add actuators to ball valves and diaphragm valves. Automation helps you control flow remotely and improves process efficiency.